OUR SOLUTIONS

Scalable, Rapid & Automated Monitoring for All Industries

- Automatic acquisition calculation, classifications & analysis

- Motion & infrastructure type detector

- Up to 350 meters range

- Quick & easy installation

Our solution simplifies 3D point cloud acquisition and processing, making it easy for anyone to set up and monitor infrastructure and industrial environments.

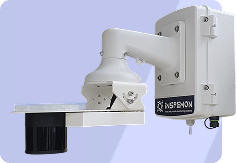

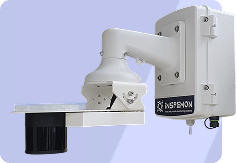

OUR DEVICES

LiDAR that adapt to every infrastructures & construction works

Railways, tunnels, bridges & industrial sites demand constant, precise supervision.

Inspemon delivers a streamlined, plug-and-play infrastructure monitoring solution for you to acquire automatic scatter plots.

Robust devices

- Durable and Weather-Resistant

- Shock and Vibration Resistant

- Long-Lasting Reliability

Easy plug-and-play

- Explanation about installation

- POE (Power Over Ethernet) for Remote Operation

- Seamless Automated Processing and Segmentation

Automatization

- Automated Data Collection

- Scheduled and Remote Operation

- Automatic identification & classification of humans, vehicles & vegetation

- Generated reports & analysis

Which device best meets your needs ?

AML001SR

Short range

AML001LR

Long range

Equipement

Structure

Aluminium

Repeatability

< 1mm

< 5mm

Range

up to 45m

up to 400m

Adjustable head

3 axes ± 20°

Integrated thermistor

Yes

Alert bipper

Yes

Height

35 cm

Width

25 cm

Depth

56 cm

IP rating

IP68

Automatic cycles

Up to 1 minute

Alimentation

PoE++ (up to 150 meters RJ45 cable)

Sensors

View

Vertical: 180° Horizontal: 360°

Vertical: 22.5° ± 1.0° (+11.25° to -11.25°) Horizontal: 360°

Channels

128

Operating Temperature

-40℃ to 85℃

Points

1,728,000

A versatile solution : Choose your network architecture

Inspemon gives you full flexibility to build the monitoring network that fits your project.

Whether you need a single Lidar, multiple synchronized sensors, or a distributed monitoring system, our solution adapts to your needs.

PREVENT ANY DAMAGES

From Reference to

Real-Time Monitoring

Inspemon’s AML solution integrates seamlessly with geotechnical, geodetic, and environmental sensors to provide continuous monitoring of civil infrastructure.

From bridges to tunnels, our automated 3D point cloud data enables rapid detection of structural changes, ensuring better safety and operational efficiency throughout the lifecycle of assets.

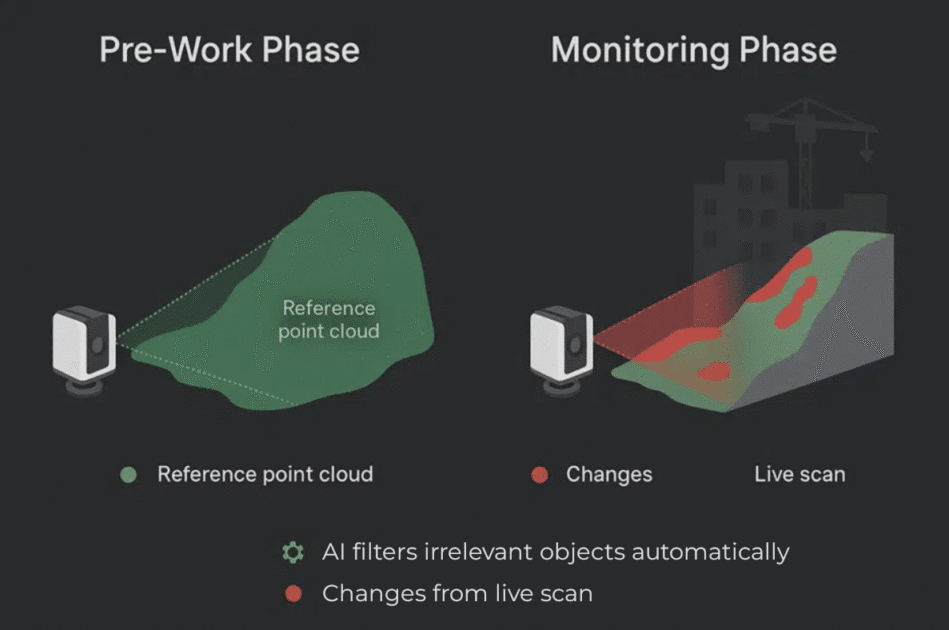

Step 1

Pre-Work Phase : Build the Reference Model

Before construction begins, our Lidar system scans the entire environment multiple times. Our platform automatically averages these scans to create a clean, high-density reference point cloud, focused only on zones of interest (e.g. foundations, walls, terrain, etc.).

Step 2

Construction & Monitoring Phase : Detect Every Deviation

As work progresses, the Lidar(s) continue scanning. Each new scan is automatically compared to the original reference model to detect any deformation, displacement or anomaly in real time.

INSPEMON CLOUD PLATFORM

Smart Software &

Data Analysis

Inspemon’s software automates point cloud assembly and classification, filtering out irrelevant data for industrial and building applications.

With AI-powered analysis, it provides automatic part dimensions and scan comparisons, streamlining monitoring and decision-making for faster, more accurate results.

AI Automatic Detection

Automatic identification & classification of :

- humans

- vehicules

- vegetation

(and automatic suppression possible)

Generated Reports

Measures & analysis automatic export

Third party integration

Integration Assembly/AI

and Acquisition via a REST API

Cloud Platform

Inspemon’s cloud platform simplifies data storage, processing, and analysis, offering seamless access to point clouds and real-time insights from anywhere, anytime.

Real-time data access

Inspemon captures high-density 3D point clouds, providing accurate, detailed representations of environments for precise monitoring and analysis.

Benefits

How does Inspemon

revolutionize your workflow ?

Cost-effective &

high accessibility

Our devices takes 1.5 hours to set up (in comparison traditional solutions can take up to 13 hours to install)

Automatic & fast 3D modeling

Our solution integrates effortlessly with your existing infrastructure, eliminating the need for complex setups or on-premise software.

Continuous Support & Improvement

We provide ongoing support and regular updates, ensuring your system evolves alongside technological advancements and changing needs.

Evolutive solution

The device can be upgraded with new sensors to boost sensitivity and range as your needs grow.

Combination of both hardware & software

Chose our SaaS plaform as the quickest & most intuitive way to analyze your data.

Fast & adaptive data collection

Data can be collected every seconds.

We have one of the fastest system.

WE ADAPT

Applications Across

Industries

Discover how can you benefit from our solutions

- Construction

- Civil Infrastructure

- Transport

- Industry & Energy sites

Construction Sector

Remote control & programming

Continuous 3D scanning on site

Smart AI-based analysis engine

Fully automated 3D acquisition & processing

Inspemon delivers automated 3D monitoring systems for construction sites, enabling real-time modeling of evolving environments. Installed statically or on mobile rigs, our systems collect and process point cloud data autonomously.

Our intelligent engine automatically classifies objects, excludes outliers, compares real conditions to digital plans, and detects structural or geometric deviations—all directly accessible on our cloud platform.

Seamless hardware + SaaS

integration for live

analytics

3D automation for site

deformation, structural

checks, and progress tracking

High-speed 3D acquisition in under 15 seconds

AI-powered anomaly detection

and data classification

Your needs

Our input

Benefits

General Contractor

Monitor progress and geometry during construction

Continuous 3D scanning + AI analysis

- Early detection of deviations

- Better planning

Site Engineers

- Prevent and detect deformation

- Prevent and detect settlement

Real-time digital twin with smart alerts

Safer operations, reduced

rework

Quality & Safety

Maintain compliance & document conditions

Automated data acquisition & traceability

Reduced errors, fast audits

BIM/Survey Teams

Compare on-site state to BIM or CAD

Automatic model-to-point-cloud comparison

- No manual post-processing

- Increase the measurement frequency

Earthwork Stability Monitoring

autonomous 3D scanning

Continuous tracking of displacement

Smart AI-based engine

Fully automated collection

Inspemon equips civil construction sites with automated lidar stations to monitor earthwork stability in real time. Embankments, temporary works, and backfills are scanned continuously. Our AI engine segments ground from machinery or vegetation, filters outliers, and identifies any displacement or deformation automatically.

Data is processed in real time on our platform, ensuring reliable alerts for early intervention—without human error or delay.

Seamless integration with site workflows

3D automation enables precise deformation alerts

Volume change detection within seconds

Earthwork geometry tracked over time

Your needs

Our input

Benefits

Construction Managers

Ensure slope & foundation

stability

Continuous 3D earthwork monitoring

Early detection of displacement

Civil Engineers

Analyze volume changes & settlement

Real-time point cloud comparison

Better risk control, fewer manual survey

Safety Teams

Prevent landslides or unexpected collapses

AI filters moving machinery, classifies terrain

Real-time alerts, enhanced safety

Project Owners

Monitor compliance with engineering plans

CAD model matching & digital twin

Quality assurance and traceability

Bridge Vibration & Alignment Monitoring

Continuous vibration and geometry analysis

High-frequency 3D scans

Integration with vibration sensors

Fully remote data acquisition and processing

Inspemon deploys fixed lidar stations and integrates with vibration sensors to monitor bridge behavior under dynamic loads (trains, vehicles). Our AI engine isolates structural features in the point cloud, filters traffic or weather-induced outliers, and highlights any deviations or abnormal vibrations.

Combined vibration and 3D data are processed in real time to create digital twins and alert stakeholders of structural fatigue or misalignment.

AI-powered detection of abnormal oscillations

Long-term evolution tracking under operational load

Remote control and instant cloud visualization

Designed for transport safety and infrastructure resilience

Your needs

Our input

Benefits

Rail Authorities

Monitor bridge safety during train passage

Monitor bridge safety during train passage

Fast anomaly detection, minimal disruption

Transport Engineers

Measure long-term structural fatigue

CAD & real-world model comparison

Better lifecycle planning & upgrades

Maintenance Team

Schedule targeted inspections

Smart alerts, AI-classified data

Save time, reduce unnecessary checks

Public Agencies

Ensure safety compliance over time

Digital twin & historical data analysis

Compliance proof, informed decision-making

Air industry

Remotely programmable & controllable

Continuous scan

Smart analysis engine

3D automatization

Inspemon designs and deploys fixed 3D scanning systems for industrial environments, capable of capturing the entire production space in seconds. All data is processed automatically through our platform, where our AI engine performs scene assembly, anomaly detection, and volume calculations.

By combining hardware with SaaS, we provide manufacturers with a turnkey solution for dimensional inspection, part verification, and logistics optimization.

3D automation for large part inspection

Seamless SaaS + hardware integration

Less than 15 seconds to capture a full scan

AI-powered point cloud classification & filtering

Your needs

Our input

Benefits

Equipment supplier

Dimensional compliance of complex parts

Automatic part inspection in 3D

Reduce scrap, increase first-pass yield

Industrial Logistics

- Flow optimization &

- Package verification

3D scan of load volumes

Fewer shipping errors, reduced waste

Maintenance & Services

Field inspection & digital twin creation

On-site 3D scanning & comparison to CAD

Targeted interventions, less downtime

Manufacturing Lines

Seamless quality control at scale

3D integration into FAL with alerts

Energy savings, higher productivity

add-ons

Complete your equipment

Add solar power, a modem for remote access, or pole mounts for easy field installation—adaptable to any site.

Communication modems

Ensure remote access and real-time data transfer with built-in 4G/5G or LoRa modems—no need for on-site retrieval.

Solar Stack Solutions

Power the device autonomously in remote areas like dams or off-grid sites—no external power needed.

Mounting & installation kits

Easily install the device on poles, walls, or custom structures with ready-to-use mounting kits—built for fast, secure setup anywhere.

Documents

Visit our resources and explore demo videos to find out more about how our solutions can be the right fit for your infrastructure monitoring needs.

How to Install and Configure Your Inspemon LiDAR

Step-by-step instructions to set up your LiDAR device, connect via PoE, and ensure accurate calibration.

This guide covers hardware installation, network configuration, and initial data acquisition for seamless integration with the Inspemon Cloud platform.

Best Practices for Automated Monitoring with Inspemon Cloud

Learn how to create automated workflows for continuous data collection and analysis.

This guide explains how to add an AML (Automated Monitoring LiDAR), set alert thresholds, and leverage AI for predictive maintenance and real-time visualization.