industries we serve

Industrial & Energy

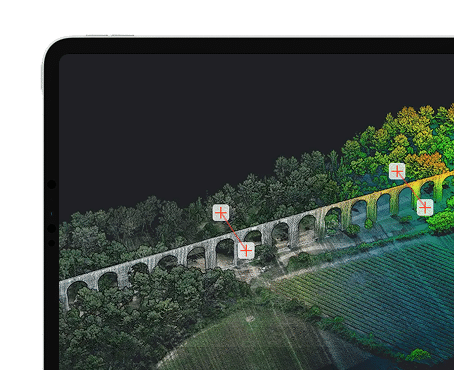

Sites Monitoring

- Dimensional Control on Final Assembly Lines (FAL)

- Traceability & Dimensional Compliance of Parts

- Real-World vs Model Comparison

- Logistics Flow Optimization

Inspemon’s Automatic Monitoring Lidar (AML) provides scalable, real-time 3D monitoring tailored for complex industrial and energy environments. By capturing dense and precise point clouds at high frequency, our solution enables proactive control of critical assets without disrupting operations.

adaptation is key

Precision monitoring for industrial and energy

sectors

Inspemon’s AML solution delivers real-time 3D insights to industrial and energy sites, enhancing safety and minimizing downtime. It integrates with geotechnical and environmental sensors for precise monitoring. Our technology ensures structural and dimensional compliance in complex environments across various sectors.

Multi-Phase Compatibility

- Enables precise monitoring across all phases: construction, commissioning, and ongoing operations.

- Facilitates continuous monitoring of both active sites and decommissioned infrastructure.

- Optimizes predictive maintenance by identifying early-stage problems and extending asset life.

Automated & Scalable

- No manual intervention required for quick and easy installation.

- Captures high-resolution point clouds at frequent intervals to track minute changes.

- Highly scalable, capable of supporting large industrial sites or multiple installations at once.

Sensor Integration

- Integrates with GNSS, inclinometers, and environmental sensors for comprehensive data collection.

- Centralizes multiple data streams into one actionable dataset for decision-making.

- AI-driven insights enhance accuracy and inform smarter, data-backed decisions.

Industrial & Energy Site Monitoring

From Production Lines to Remote Sites: Smart 3D Control & Compliance

Dimensional Control

on Final Assembly

Lines (FAL)

As a quality engineer, I use AML to automatically verify the dimensional conformity of large components in real-time on final assembly

lines—without interrupting production.

Example : Monitoring aircraft fuselage alignment during assembly..

Traceability & Dimensional Compliance of Parts

As a production manager, I use AML to ensure parts meet precise tolerances, logging 3D data for every unit to support traceability and quality audits.

Example : Controlling the geometry of wind turbine nacelle parts in a manufacturing plant.

Real-World vs Model Comparison

As a digital twin specialist, I use AML to compare the actual 3D status of assets against CAD models, detecting deviations instantly.passage.

Example : Verifying structural conformance of prefabricated modules before site delivery.

Logistics Flow Optimization

As a logistics planner, I use AML to scan spaces and assets in real-time, optimizing routing and placement of materials based on live data.

Example : Managing spatial constraints in a dense industrial warehouse with high turnover.

WE ADAPT

Monitoring Applications

Discover how our LiDARs enable monitor geotechnical, structural, environmental & remote assets.

- Assembly

- Production

- Loading

- Tracking

Dimensional Control on Final Assembly Lines (FAL)

Challenge:

Manual dimensional checks on final assembly lines are slow and prone to human error, risking quality issues and production delays.

Solution:

Inspemon’s automated 3D scanning provides rapid, precise dimensional control directly on the FAL, ensuring every assembly meets exact specifications.

Benefit:

Increase throughput, reduce scrap rates, and guarantee product quality with real-time, automated inspection.

Automatic Part Inspection During Production

Challenge:

In-line part inspections often rely on spot checks, missing defects and causing costly recalls.

Solution:

Continuous automatic 3D inspection of parts during production detects deviations instantly, enabling immediate correction.

Benefit:

Minimize defects, improve yield, and maintain consistent quality without slowing manufacturing

Logistics & Supply Chain Automation

Challenge:

Manual verification of loading and packaging is time-consuming and error-prone, risking damage and shipping errors.

Solution:

Automated 3D scanning quickly and reliably verifies load geometry and packaging correctness before shipment.

Benefit:

Ensure safe transport, reduce returns, and improve customer satisfaction with efficient automated load inspection.

Automated 3D Volume Scanning — Real Condition vs. Model Tracking

Challenge:

Monitoring the actual condition of industrial assets against design models is difficult and slow without manual surveys.

Solution:

Inspemon’s automated 3D scanning continuously compares as-built conditions to CAD models, instantly highlighting deviations.

Benefit:

Facilitate maintenance, detect wear early, and ensure compliance with design standards—saving time and cost.

wide range of action

Our solutions

Inspemon got you covered from hardware to software.