industries we serve

Construction

Monitoring

- Earthwork Stability & Geotechnical Monitoring

- Structural Deformation Control

- Environmental Impact & Site Compliance

- Progress Tracking & Geodetic Precision

Inspemon offers automated, real-time monitoring of construction sites with high-resolution point clouds. Our solution tracks structural movements, material changes, and potential risks, ensuring projects stay on schedule and within safety standards. It enables proactive decision-making and efficient project management.

adaptation is key

Built for Construction.

Ready for Every Phase.

Inspemon adapts seamlessly to all stages of construction—from planning to maintenance—by combining automated 3D data capture with integration of geotechnical, geodetic, and environmental sensors.

This flexibility ensures precise, real-time insights that improve safety, decision-making, and project efficiency on any site.

Multi-Phase Compatibility

- Adapts to all construction stages: pre-, during, and post-construction

- Delivers consistent 3D data over time for better tracking

- Supports lifecycle monitoring and documentation

Automated & Scalable

- Installs quickly with no manual surveying required

- Captures dense point clouds automatically, every few seconds

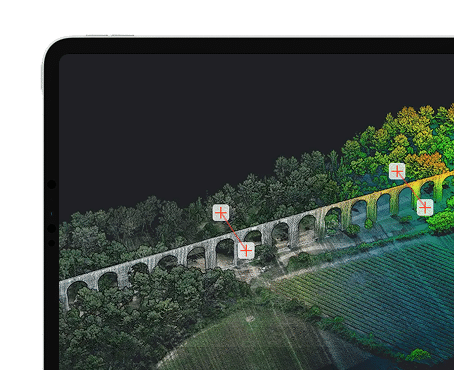

- Easily deploys across multiple locations or large areas

Sensor Integration

- Connects with GNSS, inclinometers, and weather stations

- Centralizes geotechnical, geodetic, and environmental data

- Enables smarter, cross-validated decision-making

construction monitoring

We enable monitoring & connectivity in a wide range of areas

Earthwork Stability & Geotechnical Monitoring

As a geotechnical engineer, I use AML to monitor soil displacement and slope stability in real-time, integrating with inclinometers and piezometers for a full geotechnical picture.

Example : Embankment stability tracking during highway construction.

Structural Deformation Control

As a structural engineer, I use AML to capture high-density 3D data of critical structures like retaining walls or foundation slabs, detecting early signs of deformation.

Example : Continuous scanning of crane foundations on a high-rise project.

Environmental Impact & Site Compliance

As an environmental manager, I use AML to monitor excavation zones, runoff patterns, and vegetated buffer zones—automatically documenting changes.

Example : Tracking sediment control barriers around a construction site near a protected area.

Progress Tracking & Geodetic Precision

As a site manager, I use AML combined with GNSS and total station benchmarks to measure progress with centimeter-level accuracy, without disrupting workflows.

Example : Monitoring concrete pouring and formwork alignment over time.

WE ADAPT

Monitoring Applications

Discover how our LiDARs enable monitor geotechnical, structural, environmental & remote assets.

- Geodetic

- Geotechnical

- Environmental

- Structural

Real-Time Monitoring for Urban Construction

Challenge:

During metro tunnel excavation beneath a dense city block, nearby buildings risk ground settlement or structural damage. Traditional surveys can’t detect shifts in time to act.

Solution:

Inspemon’s automatic lidar stations continuously scan the tunnel zone and surrounding buildings, detecting millimetric deformations in real-time—without interrupting construction.

Benefit:

Prevent costly damage, ensure public safety, and maintain compliance with urban risk management protocols through 24/7 automated geodetic monitoring.

Integrated Monitoring for Urban Construction

Challenge:

Excavating tunnels beneath urban infrastructure risks ground settlement and structural impact on nearby buildings. Traditional sensors like MPBXs, tiltmeters, or inclinometers provide only localized data, often missing broader surface deformations.

Solution:

Inspemon’s AML (Automatic Monitoring Lidar) adds continuous 3D surface scanning to complement point-based instruments—delivering real-time, spatially rich insight into ground and structural movements above the tunnel.

Benefit:

Correlate deep movement data with visible surface shifts, detect early warning signs across wider zones, and ensure safer, more precise tunneling in complex urban environments.

Environmental Insight for Urban Construction

Challenge:

Urban tunneling impacts—and is impacted by—its environment. Temperature shifts, heavy rain, or excessive noise can influence ground behavior and public safety. Yet, these factors are often monitored separately from structural sensors.

Solution:

Inspemon’s AML system integrates 3D deformation data with real-time environmental monitoring—combining lidar with weather (rain, temperature, humidity) and noise sensors for a unified risk analysis.

Benefit:

Correlate environmental events with ground movement and structural responses. Detect patterns like rain-triggered settlement or vibration-induced tilting. Anticipate risks, improve resilience, and optimize construction planning.

Structural Health Monitoring in Urban Construction

Challenge:

Urban tunneling can cause micro-cracks, vibrations, and structural stress in nearby buildings. Isolated crackmeters or vibration sensors detect local anomalies but lack context for broader structural behavior.

Solution:

Inspemon’s AML (Automatic Monitoring Lidar) complements structural sensors by delivering full 3D scans of façades and foundations, allowing real-time correlation with crack width changes and vibration events.

Benefit:

Link structural changes to precise spatial deformation data. Identify early signs of damage, trace the source of vibrations, and prioritize intervention before issues escalate—ensuring safety in dense urban areas.

wide range of action

Our solutions

Inspemon got you covered from hardware to software.