From Hours to Minutes :

Automatic Monitoring

with Point Clouds

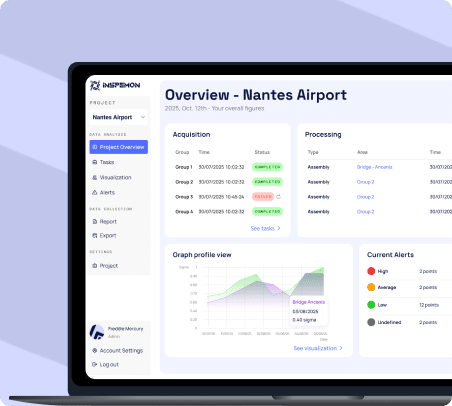

Inspemon delivers a streamlined, plug-and-play infrastructure monitoring solution to process automatic collection of scatter plots.

OUR SOLUTIONS

Discover the building blocks of our next-generation monitoring solutions

We empower you to deploy secure, scalable and automated monitoring networks that deliver real-time, high-precision data directly to your systems without the complexity.

PREVENT ANY DAMAGES

Preventing Risk Through Automation & Continuous Monitoring

Inspemon’s automated point cloud acquisition and cloud-based processing reduce human error, ensuring accurate data.

early issue detection

proactive maintenance

faster, more informed decisions-

minimizing risks & costly failures

OUR CLIENTS

Industries

We Serve

From Europe’s busiest railways to industrial giants, Inspemon simplifies monitoring for sectors where precision and safety are paramount.

WHO WE ARE

Why Infrastructure

Leaders Choose

Inspemon.

Precision & Automation

Risk Prevention

Cost-Efficiency

Faster Decision-making

Partnering with Inspemon means more than just installing hardware—it’s a commitment. Our team supports you from initial network design to ongoing system optimization, ensuring your monitoring solutions exceed expectations.

Additional Services:

- Project Design & Deployment Support

- Custom Sensor & Network Configuration

- On-site Training & Pre-Configuration

- Fast Post-sale Support & Maintenance

Our guarantees.

Accuracy & Precision

We guarantee high-resolution, reliable data capture with minimal margin for error, ensuring accurate monitoring at every stage.

Seamless Integration

Our solution integrates effortlessly with your existing infrastructure, eliminating the need for complex setups or on-premise software.

Continuous Support & Improvement

We provide ongoing support and regular updates, ensuring your system evolves alongside technological advancements and changing needs.

We make it easier.

Inspemon simplifies infrastructure monitoring by automating data capture, processing and analysis, saving time, reducing complexity & delivering actionable insights faster.

Ready to make the switch to real-time,

automated monitoring?